The LNF Sputtering Chamber

The LNF Sputtering Chamber F. Ronchetti, P. Di Nezza, A. Orlandi, W. Pesci, A. Viticchie'

Introduction

The EMCAL is a modular sampling calorimeter: each of the 3168 modules is composed by 4 optically isolated towers made out of a Pb-scintllator sandwich. The independent optical readout of each tower is provided using wavelength shifting fibers coupled to an Avalanche Photo Diod. Scintillation photons produced in each tower are captured by an array of 36 Kuraray Y-11, double clad, wavelength shifting (WLS) fibers that run longitudinally through the Pb-scintillator stack (figure 1).

Figure 1 - EMCAL module with optical and electronic readout

Each fiber is terminated in an aluminized mirror at the front face end of the module.

Light paths into a mirrored fiber

The fiber bundles are pre-fabricated and inserted into the towers after the module mechanical assembly is completed. The 36 individual 1 mm-diameter fibers are packed into a circular array 6.8 mm in diameter and held in place inside a custom injection molded grommet by Bicron BC-600 optical cement. An optical quality finish is applied to the assembled bundle using a diamond polishing machine.

The optical characteristics of the Y-11 fibers are shown in the following summary table:

At the opposite end of the bundle, fibers are tooled using an ice-polishing technique and mirrored with a coat of aluminum to recover the light travelling in the direction opposite to the APD coupled end.

Figure 2 - Comparison of light yield between fibers with and without mirror

Tests were made with and without mirroring applied to the polished fiber end, and transmitted light was recorded with an Avalanche Photo Diode (APD) photo-sensor as a

function of position of the light injection point. Typical results are shown in figure 2. The lower curve shows the light transmission efficiency in arbitrary units as a function of distance from the APD for a fiber without mirrored end. The upper curve shows the effect of including mirroring on the fiber. The response is considerably flatter with an overall increase in efficiency in the range of about 25% in the vicinity of shower maximum (i.e. the location of the highest energy deposition for an electromagnetic shower). Shower maximum occurs at about 26 cm on the distance scale shown.

Optical fibers preparation and tooling

The film deposition is performed in a high (10-7 torr) vacuum chamber where an aluminum target is eroded by means of an ionized gas (sputtering). In the following pages we will give an overview of the technical aspects of this procedure and report about the preliminary studies we have performed to optimize the system construction.

Figure 3 - Frozen bundle hold by a urethane ring

In any case, before entering the film deposition vacuum chamber, the Y-11 optical fibers must be suitably tooled by polishing the ends that will be the substrate for the aluminum deposition.

To this aim, the fibers are bundled in groups of ~300 using an urethane hexagonal holder. The end of the bundle to be polished is immersed in distilled water which fills the interstitial spaces between fibers. Then the bundle is kept in a freezer at – 20°C (figure 3) for roughly 12 hours to allow the water to freeze and the urethane ring to strengthen up.

Once the bundle is completely frozen and the urethane ring is rigid, the bundle is ready for machining: the end to be polished is kept for few minutes into a bottle containing liquid nitrogen to increase the overall stiffness of the system and after that, the bundle is polished using a spinning wheel rotating at ~ 2000 RPM.

The wheel has three cutting tools (2 carbon and 1 diamond) positioned at different radii which perform the cutting with an increasing degree of precision. This polishing technique ensures a cutting planarity similar to the one obtained using a custom-built single-fiber polishing machine which would be extremely expensive and yield a much lower production rate, incompatible with the EU EMCAL construction timeline which foresees the processing 130.000 fibers (corresponding to 864 EMCAL modules) at the LNF in three years

The sharpness of the cut and its perpendicularity to the fiber axis are crucial. In fact, since the tooled fiber ends must act as mirrors, any deviation of the cut from the perpendicular plane will spoil the reflection of the deposited aluminum layer making the light to travel out of the fiber transmission core: the example below shows the effect of an aluminum film deposited on a non-perpendicular cut.

Out-of-core light propagation in the fiber

Once the bundle is fully polished the urethane ring can be removed and the resulting fibers are inserted into a Teflon holder ring (figure 4). In fact, the film deposition requires a temperature inside the vacuum chamber of several tenths of °C so that the urethane ring will become too soft to hold the bundle together. Teflon has a much better behavior in this sense, being more stiff than urethane but not to hard to spoil the fiber cladding when the bundle is very tight. To keep the fibers enough tight one or two dummy fibers can be inserted at last into the bundle.

Figure 4 - Teflon fiber holder

The picture shows a polished fiber bundle and the Teflon ring

used hold the bundle in the film deposition chamber.

Overview of the sputtering process

The aluminum film deposition is done using a sputtering target. Sputtering is a process whereby atoms the target materials are ejected into the gas phase due to bombardment energetic ions (figure 5).

Figure

5

- Target bombardment by

gaseous ions

The number of atoms ejected from the surface per incident ion is called the sputter yield and is an important measure of the efficiency of the sputtering process. Other things the sputter yield depends on are the energy of the incident ions, the masses of the ions and target atoms, and the binding energy of atoms in the solid.

Figure 6 - Plasma confinement on the target surface

The ions for the sputtering process are supplied by plasma that is induced

in the sputtering equipment. In practice a variety of techniques are used to

modify the plasma properties, especially ion density, to achieve the optimum

sputtering conditions, including usage of RF (radio frequency) alternating

current, utilization of magnetic fields, and application of a bias voltage to

the target.

Plasma confinement on the target surface is achieved by locating a permanent magnet structure behind the target surface (figure 6).

Inert gases, specifically argon, are usually employed as the sputtering gas because they tend not to react with the target material or combine with any process gases and because they produce higher sputtering and deposition rates due to their high molecular weight.

Positively charged argon ions from the plasma are accelerated toward the negatively biased target (cathode), resulting in material being sputtered from the target surface.

Sputtered atoms ejected into the gas(argon) phase are not in their thermodynamic

equilibrium state. Deposition of the sputtered material tends to occur on all

surfaces inside the vacuum chamber.

Sputtering is used extensively in

the semiconductor industry to deposit thin films of various materials in integrated

circuit processing. Because of the low

substrate temperatures used (< 80°C) , sputtering is an ideal method to

deposit the required aluminum layers on plastic optical fibers. The same

condition is valid for contact metals for thin-film transistors. This is in

contrast, for instance, to thermal evaporation techniques where the substrate temperature

tends to be higher. Sputter deposition also has an advantage over molecular

beam epitaxy (MBE) film deposition due to its speed.

Sputtering sources (magnetrons) utilize strong electric and magnetic fields to trap electrons close to the surface of

the magnetron, which holds the target. The electrons follow helical paths

around the magnetic field lines undergoing more ionizing collisions with

gaseous neutrals near the target surface than would otherwise occur. Extra

argon ions are created as a result of these collisions and leads to an increase

of the deposition rate. It also means that the

plasma can be sustained at a lower pressure (10-2 torr). The

sputtered atoms are neutrally charged and so are unaffected by the magnetic

trap.

Charge build-up on insulating targets can be avoided with the use of RF sputtering where the sign of the

anode-cathode bias is varied at a high rate. RF sputtering works well to

produce highly insulating oxide films but only with the added expense of RF

power supplies and impedance matching networks. Stray magnetic fields can leak from

the sputtering target but only in the case of ferromagnetic materials (specially

designed sputter guns with unusually strong permanent magnets must often be

used in compensation).

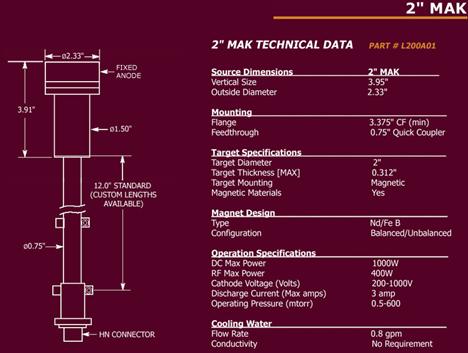

The 2” MAK magnetron sputter gun. The photo shows the 2” target-mounting

surface, the vacuum feed-through, the power connector and the water lines. On

the side, the 99.999% pure 2” Al target used in the LNF sputtering station.

Preliminary vacuum studies at LNF

To design the sputtering system used by our project, a series of preliminary tests were carried out at the LNF using a stainless steel vacuum chamber and a bundle of 500 optical fibers, 40-cm long and 1.5 mm in section. The test setup is shown in figure 7.

Figure 7 - Equipment for vacuum studies used at the LNF

The aim of the test was to

determine the influence of the fibers and chamber walls out-gassing on the time

needed for the pumping system to reach a vacuum pressure of

10-7 torr which is our set point pressure value for plasma ignition.

Let us briefly describe the test setup: the physical and mechanical parameters characterizing the test system are listed below:

Vacuum chamber:

• walls material: stainless steel

• internal geometrical volume: ~11 liters

Fibers:

• bundle of 500

• length: 40 cm

• geometrical volume: 0.5 liters

• geometrical surface: 1 m2

Gas/pumping system:

• 15 m3/h oil free piston pump

• 300 l/s oil free turbo-molecular pump

• N2 refill line

• vacuum meter

The piston and turbo pumps were used in a series, as can be seen from the picture showing the test apparatus. The piston pump is needed to kick-start the vacuum into the chamber and goes down to 10-3 torr. At this pressure value the turbo-molecular pump can start to work, too.

Figure 8 - Results of vacuum studies performed under different working conditions

Vacuum curves obtained with different test conditions are shown in figure 8. First of all the chamber flange was closed without inserting the fiber bundle (empty chamber). The resulting curve is the light blue dotted line which shows a 4-hour rate in the pressure drop to 10-7 torr. This behavior is influenced by the chamber steel walls out-gassing.

The second test is represented by the pink dotted curve. After the first vacuum was created in the chamber, and the light blue dotted line was measured, we considered the walls “out-gassed” and a 10-minute air refill of the chamber was allowed. After the air refill pumping resumed. The new (pink dotted) curve shows a clear improvement in the pressure drop rate over the previous condition.

A third test was performed using the N2 refill line installed in our test system. This line allowed us to fill the chamber volume with nitrogen before allowing the outside air in. Nitrogen helps to maintain the outside air contamination of the chamber walls low. In fact we see that, after the N2 / air refill, the pumping system brings back the vacuum condition in the chamber reaching 10-7 in roughly 40 minutes (green dotted line).

At this point the fiber bundle was inserted into the chamber. The test was resumed out-gassing the chamber + fiber set. The result of this setup is the dark blue solid line which exhibits a very slow rate in pressure drop. At first, this was interpreted as a consequence of the fibers being “dirty”.

To clean up the fibers, ultrasonic bath followed by oven baking at 40 °C were performed on the bundle. After this treatment we put back the fibers into the chamber and started pumping once again, obtaining the light blue solid line, which shows similar result with respect to the previous condition. At this point is clear that the main effect slowing down the pressure drop with the bundle in the chamber is the lack of fibers out-gassing, not the fibers being ‘dirty’.

The procedure which produced the light blue solid curve, lead us to the point where we could consider the fibers out-gassed. To simulate a working condition where the chamber should be opened and an out-gassed fiber bundle inserted into it, a 45-minutes N2 refill followed by outside air was allowed.

After the refill we resumed pumping obtaining the green solid curve which shows an improvement in the pressure drop. Extrapolating from the graph we see that reaching the pressure of 10-7 torr (which we regard as our set point) can be done in approximately 12 hours.

Figure 8 shows also a 45-minutes N2 / air refill vacuum curve represented by the green soild+diamonds line which is the result of a similar test performed two month before the one we just discussed. From this additional curve we see that the pressure drop was faster after the N2 / air refill even if the pumping conditions were the same. We may explain this as a consequence of the increased humidity in outside air. In fact the green solid+diamond curve was obtained in June with the system positioned in a air conditioned room, while green solid curve was obtained in August in a very hot, humid, and non conditioned room.

Let us summarize the vacuum test runs under different conditions:

· Empty chamber: no outgas

· Empty chamber: outgas

· Empty chamber: nitrogen feedback

· With bundle of 500 fibers: no cleaning, no baking, no outgas

· With bundle of 500 fibers: cleaning, baking, no outgas

· With bundle of 500 fibers: nitrogen feedback, cleaning, baking, outgas

The result of this test suggests the possibility of using an additional out-gassing chamber to keep the fiber bundles in optimal out-gas condition before inserting them into the sputtering system. This setup would imply a second turbo-pump to maintain a 10-5 torr pressure in the stocking chamber, leading to a more complex and expensive pumping system. To keep a simpler design and prices down, we decided to go for a more powerful single-pump system using a 850 l/s turbo pump in series with a 25 m3/h piston pump.

Both pumps are oil-free to avoid back diffusion of oil molecules into the chamber.

Chamber design

The LNF sputtering chamber is designed to handle the bundle of 300 optical fibers described above in the text in the vertical position. Each Y-11 fiber is 1.0 mm in diameter and 40 cm in length. This physical parameter is different from what we used in the test setup since the test fibers were thicker. The chamber assembly is made out of one main stainless steel cylindrical trunk with two vertical branches (figure 10).

The main trunk (160 mm diameter) has a CF flange on the back to accommodate a gate valve. This valve is used to establish a regime pressure to control the argon flux when the plasma is ignited and sputtering process is steady. The opposite side of the gate valve has a flange for the connection of the turbo-molecular pump. On the front side of the main trunk, a second flange is present to allow for the chamber sealing: this flange has also a quartz inspection window from which the operator can check the presence of the plasma.

From the main truck depart two vertical braches. The upper branch (diameter 100 mm, length 500 mm) allows for the fiber bundle insertion and containment. In fact, the Teflon-hold side of the bundle must reach the proximity of the sputtering aluminum target. Between the bundle end and the sputtering source we install a shutter system controlled by a film deposition monitor.

Figure 9 - Film deposition probe

This monitor consists of a oscillator circuit which frequency changes according to the deposited film. The oscillator itself (figure 9) is placed nearby the substrate and receives a film deposition. When the required amount (200 nm) of aluminum is accumulated on the substrate/oscillator the deposition monitor activates the shutter motor, thus shading the area in front of the substrate (the bundle end) and turning off the power to the magnetron source.

Figure 10 - Sputtering chamber (2D view)

The lower branch has one flange to allow for the magnetron gun with the sputtering source insertion. A 3D view of the station is shown in figure 11:

Figure 11 - Sputtering chamber (3D view)

where the upper trunk with 3 service flanges is shown. One of the flanges is used to connect a vacuum monitor. The upper trunk is sealed with an ISO-K flange to minimize the time required to remove the aluminized bundle and re-insert a new one for processing.

On the main trunk we see two service flanges on one side: one of them allows the insertion of the film deposition monitor oscillator and the other one may be used to install a motorized shutter to protect the quartz window from getting aluminized, too.

The gate valve is shown together with its gate-control (the handle) which can be manually adjusted to choke the turbo pump to keep the Argon flux steady when the sputtering (plasma) regime is reached. Below the main trunk, in correspondence with the top part of the branch, the magnetron gun head and target source. On the opposite side, partially hidden by the chamber 3D image we have shutter mechanism for the substrate.

Figure 12 - Fiber bundle into the sputtering chamber

Figure 12 shows a fiber bundle being sputtered. The light is from the plasma near cycling near the sputtering target. The aluminum layer deposited on the fibers is 200 nm. The thickness has been chosen to protect the aluminum in the bulk of the layer from oxidation, since we need the best light reflection at the Al-fiber interface so that this zone has to be oxide-free to maximize the light yield back into the fiber core. To obtain this protection layer we simply use a thicker Al deposit, allowing for natural oxidation of the outer layer. The alternative was to deposit Al2O3 on the Al layer in contact with the fiber to protect the outer part of the mirror. This seemed an unnecessary complication since it would imply the use of a different sputtering target and a more sophisticated target holder.

References

1.

Elizabeth Gallas and Jia Li, Polishing Optical Fibers for

the D0 ICD in Run II,

FERMILAB-TM-2062, 1998

2.

P. Hanlet, M. Marcus and E. Gallas, Comparison

of Fiber Polishing Techniques,

FERMILAB-TM-2068, 1999

3.

Plasma surface engineering

corporation,

Technology note: TN 000 100 02/03

4.

ALICE, The Electromagnetic Calorimeter (addendum to the technical proposal),

CERN-LHCC-2006-014, CERN/LHCC 96-32-Add3